Project Description

Dimensionally Accurate Die Cast Dies and Injection Molds

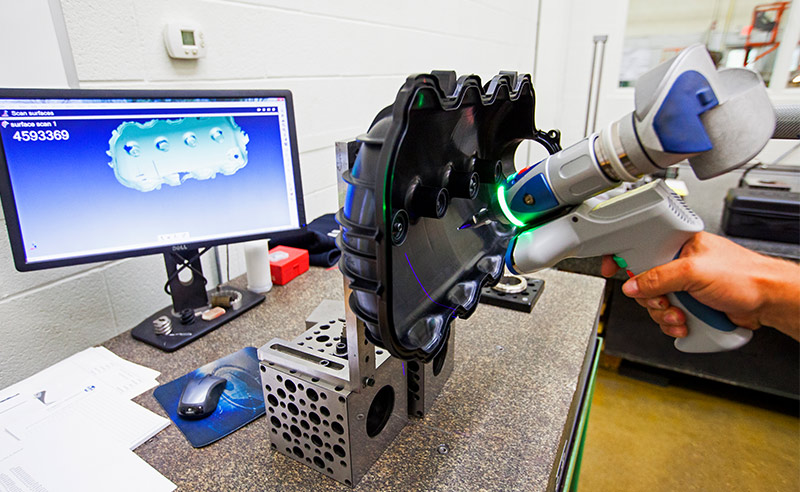

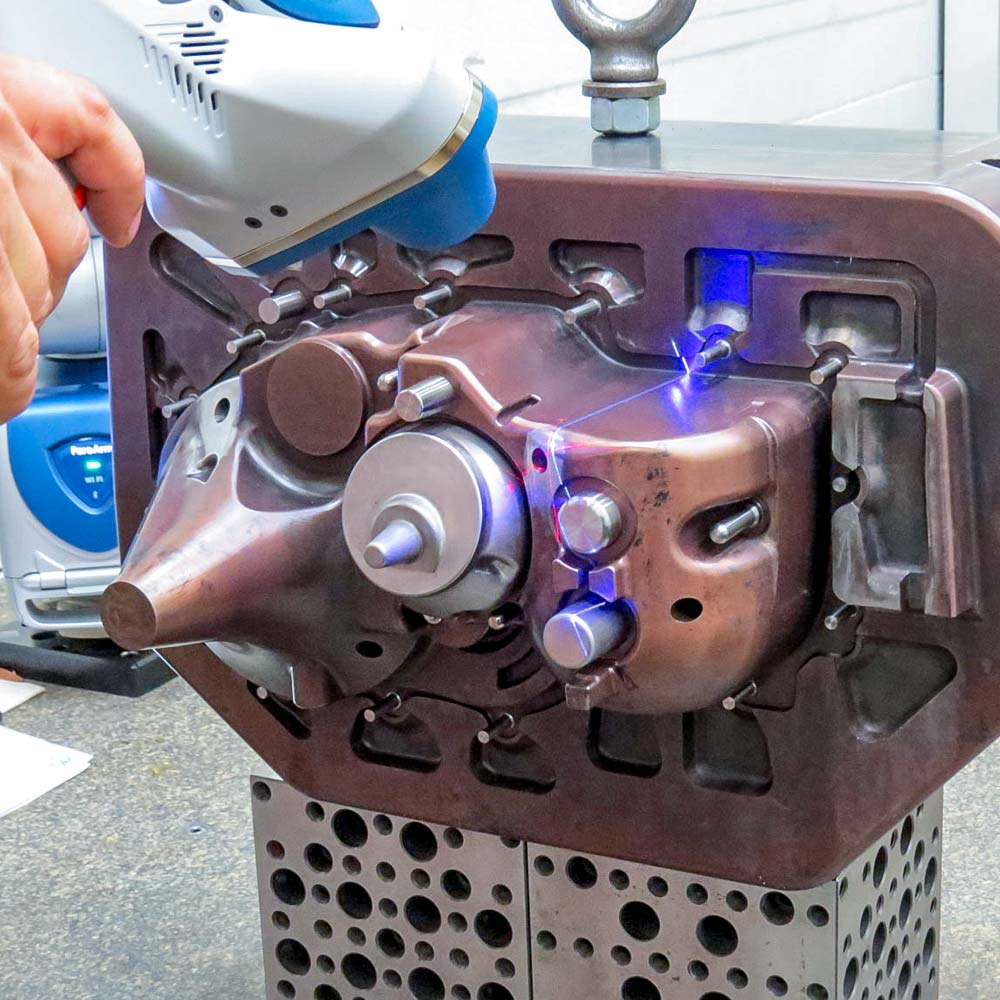

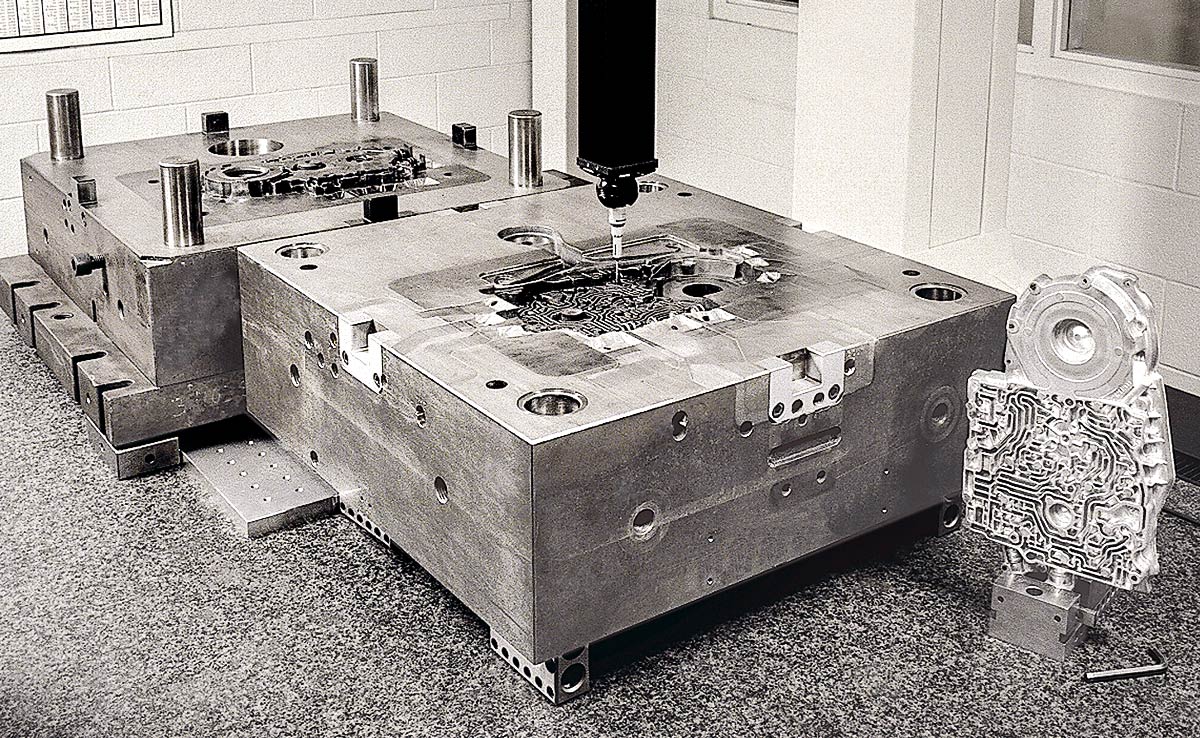

Featuring the latest laser scanning technology and touch-sensitive probes, Hanson’s coordinate measuring machines (CMMs) verify mold and die tooling components and provide records of dimensional readings. By utilizing the latest inspection software, our CMM operators are able to check electrodes, cavity steel, and final parts against the original CAD models developed by our engineering and programming departments.

Our die spotting presses provide further verification of die accuracy and contact surfaces, especially advantageous in high pressure die casting processes.

REASON #5 REDUCING COSTS

Using SolidWorks, NX, Catia and Magma5 technologies, our designers prove out optimal filling characteristics and shortest cycle times while avoiding gas inclusions, porosity and cold lapses.